Impact of barite and ilmenite mixture on enhancing the drilling mud weight

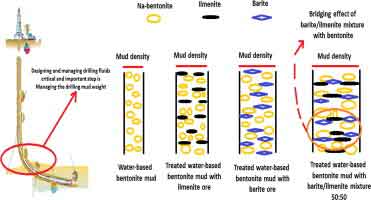

It is common knowledge in the technology of drilling fluids, monitoring of the drilling mud weight is critical in developing a mud system that yields good well stability. Alternative weighting materials should be in demand to offer superior properties such as barite, available insufficient reserves to meet field requirements, and be competitively priced. A weighting material that can be sourced locally to substitute barite would be a good innovation in the drilling industry. The present work was performed to the enhancement the weighting of the drilling fluids by using a mixture of barite and ilmenite. Micro-sized ilmenite ore (FeTiO3) particles were obtained by a direct solid-phase milling process to replace a certain percentage of barite as weighting material of the drilling mud. X-ray diffraction (XRD) analysis was carried out to underline the phase identification of the crystalline ilmenite, used drilling mud weighting agents as barite and Na-bentonite particles. The lamellar shape and the arrangement in overlapping plates of ilmenite particles, Platy-like shaped Na-bentonite grains against sub-angular and square-shaped barite particles were confirmed by scanning electron microscope (SEM) technique. Three mud samples with different densities were prepared which be made up of freshwater, sodium bentonite, and weighting material. The weighting materials were added up to the mud separately to form the required mud density ranges between 8.65 and 18 lb/gal. The first sample was water-based mud with barite; the second sample was water-based mud with local ilmenite ore and the third sample was water-based with barite and ilmenite in which were added in parts as 50:50 by ratios. These samples were investigated at different temperatures (normal, 120, 160, 180 °F) and the employed mud density range to determine solid content, density, rheological properties, and filtration losses. The study showed that the rheological properties of barite/ilmenite mixture were found to give comparable results as barite and has the potential to be used as alternative weighting material especially in heavier drilling mud. Two significant advantages could be observed through using the mixture; it produces lower solids content and fluid loss which in turn reduces the formation damage, respectively.

- Barite/ilmenite mixture (BIM) has the potential to be used as alternative weighting material to barite in drilling mud.

- The rheological properties of barite/ilmenite mixture are similar to that of barite and therefore could be used in place of barite.

Drilling fluids play sophisticated roles in the drilling process: stabilizing the wellbore without damaging the formation, keeping formation fluids at bay, clearing cuttings from the bit face and lubricating the bit and drill string. Weight materials are compounds that are dissolved or suspended in drilling fluid to increase its density. They are used to control formation pressures and resist the effects of sloughing or heaving shale’s that may be encountered in stressed areas [1]. A critical property differentiating the effectiveness of various wellbore fluids in achieving these functions is density or mass per unit volume. The wellbore fluid must have sufficient density in order to carry the cuttings to the surface. Density also contributes to the stability of the borehole by increasing the pressure exerted by the wellbore fluid onto the surface of the formation downhole. It has been long desired to increase the density of wellbore fluids, and not surprisingly, a variety of methods exist. One method is adding dissolved salts such as sodium chloride, calcium chloride, and calcium bromide in the form of aqueous brine to wellbore fluids. Another method is adding inert, high-density particulates to wellbore fluids to form a suspension of increased density. These inert, high-density particulates often are referred to as “weighting agents” and typically include powdered minerals of barite, calcite, or hematite.

The main role of the weighting materials in the drilling fluid is to increase density and ultimately to ensure borehole stability. It creates also sufficient hydrostatic pressure in the hole and minimizes fluid loss by the formation of thick filter cake on the walls of the well. An increase in density also results in increasing the penetration rate; however, when the density is excessive, it can cause differential sticking of the drill string. Barite (BaSO4) is chemically inert and insoluble. It occurs as a vein filling and as a gangue mineral in silver, zinc, copper, nickel, and lead ores. Barite with a specific gravity of 4.2–4.4 and hardness 2.3–3.5 has been the most common weight material for drilling fluids. The demand of the free world is now approximately 2 million tons per year corresponding to 55% of the total barite production.

The choice of weighting agent to be used in drilling fluids is determined by the need to

- Provide low rheology (low plastic viscosity) particularly in high-density fluids.

- Show low settling tendency and providing low sag.

- To be easily removable from the reservoir by mechanical or chemical means.

- To be hard enough not to create fines during drilling which may cause formation damage or high gel values.

- Should contain a minimum of coarse particles to prevent abrasion.

- To be sustainable and readily available and in large quantities.

- To be cost-effective.